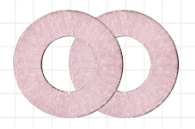

The friction plate of the chain hoist is an important component of the braking system. It is located inside the cover of the chain hoist, on both sides of the ratchet wheel, and is driven by the kinetic energy of the hand to approach the ratchet wheel to achieve deceleration effect. It is not as eye-catching as lifting chains, manual chains, and casings. It is difficult for us to notice it without disassembly, so how often should we inspect the friction plate?

If the lifting operation is frequent, strictly speaking, the friction plates should be inspected before each lifting operation, because the integrity of the braking system is the greatest guarantee for the safety of the operator's life at all times. Frequent use of chain hoists requires frequent inspection of friction plates and corresponding measures should be taken based on their degree of wear.

Another situation is that there are not many lifting operations, every few days or even months. Most of the time, the chain hoist is a tool for pressing the bottom of the box. So, after the first inspection, if it is not used halfway, there is no need to test it again for the next use? Of course not. Under the long-term "strike" state of the chain hoist, the wear of the friction plate is indeed very low, but do not ignore an external environmental factor. The harsh environment, humidity, or excessive dust can all potentially invade the interior of the casing, and the intrusion of foreign objects and impurities can directly affect the operation of the braking system. So even for the "bottom pressing" chain hoist, we need to test it once every half a month to a month, and then test it again before use.

Only by achieving effective detection can we work with peace of mind.